Options and Customizations for Standard Module System

Floating Attachment

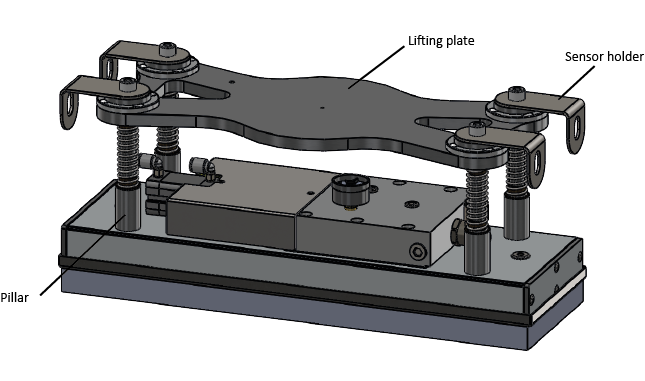

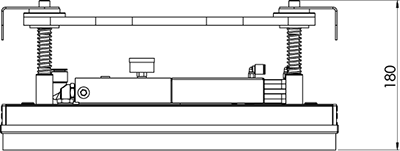

The floating attachment is a popular accessory available for all SMS 80 and SMS 120 grippers. The floating attachment consists of four pillars, along which a lifting plate can slide up and down.

The floating attachment allows the SMS unit to move vertically relative to the robot, gantry or similar device to which it is attached. This means that the SMS unit can be aligned with the object to be lifted, even if the object is not aligned with the device. The floating attachment also helps getting a good compression of the foam pad before activating vacuum to lift an object.

The floating attachment is equipped with four sensor holders, which, if equipped with sensors give a signal when the gripper is properly placed on the object and thus provides an indication when it is time to activate the vacuum.

Sensors

SMS 120 and SMS 80 grippers are equipped with analogue vacuum gauges by default. As option they can be equipped with vacuum sensors with digital display and output.

The floating attachment can be equipped with indictive sensors to give indication when the gripper is on the product.

| Digital Vacuum Switch | 340 346 620 |

| Analogue Vacuum Gauge | 340 346 610 |

| Inductive Sensor for Floating attachment | 340 341 207 |

Pneumatic Valves

Pneumatic valves for controlling the compressed air flow to grippers with ejectors. A 5/3 valve allows the compressed air to either be used for vacuum generation, reverse blowing as well as being switched off.

Both sizes of valves below are 5/3 valves with, closed mid position. 24V DC, incl. DIN connector

| Large Valve | |

|---|---|

| 1 valve is recommended to for grippers with up to 1365 Nl/min air consumption | |

| 340 346 641 |

Customizations

The Standard Module System opens up for many kinds of customizations, which may be needed for getting the right function of the SMS unit. Making customizations quickly and efficiently is a core competence of the UniGripper organization and the customization possibilities range from minor changes as in foam pad design, to modifications of the SMS profile and further on to lifting systems integrating multiple SMS units. Below are the most common customizations presented and characterized in terms of degree of customization. Contact us to find the best solution for your needs.

Foam Pad Thickness

For all SMS units apart from the SMS Mini series, the default foam pad thickness is 20mm. In case the surface handled objects have a lot of height variation, a thicker foam pad might be needed. For other applications a foam pad thinner than 20mm might be the best option.

Foam Pad Material

By default, the SMS unit is equipped with a high-quality generic foam material. UniGripper offers a broad range of foam materials for different specific needs; from foam pads with extra wear resistance to foams for food applications.

Foam Pad Design

By modifying the design of the suction holes in the foam pad, the SMS gripper can get new abilities, like handling empty glass jars, lifting thinner or smaller objects or lifting heavier objects.

Foam Carrier Size

Broadening the foam carrier plate allows wider distribution of the vacuum and can increase the lifting force on an object.

Gripper Length

Sometimes the standard lengths of the SMS are not quite right. The length of the SMS can be customized anywhere in the interval of 30-6000 mm.

Valve Configuration

The standard valve configuration available for the SMS gives good options for almost any scenario. Sometimes, however, other configurations may be more beneficial